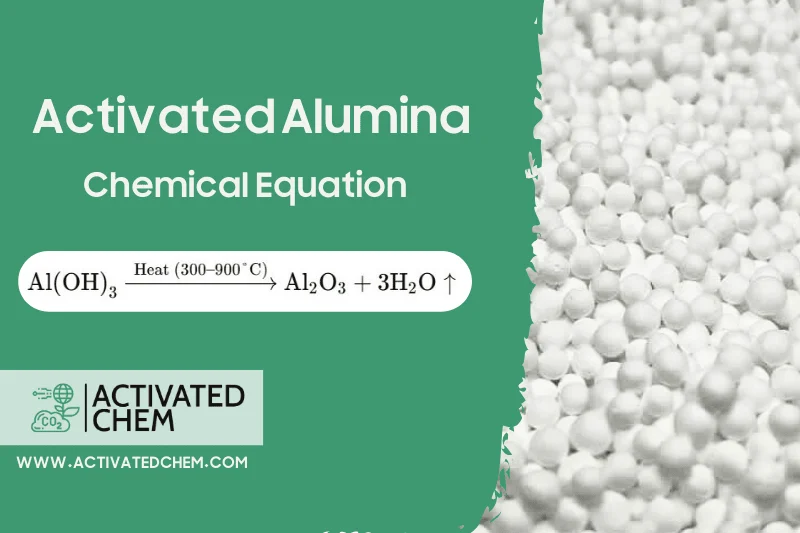

Activated alumina is a specialized aluminum oxide (Al₂O₃) form for enhanced adsorption. It differs from conventional alumina used in aluminum manufacturing because it effectively captures moisture, gases, and impurities. Manufacturers produce activated alumina by heating aluminum hydroxide (Al(OH)₃) to temperatures between 1000 and 1100 degrees Celsius. This process creates a highly porous material with a surface area reaching 350 m²/g.

At ActivatedChem, we specialize in high-quality activated alumina solutions for various industrial applications. The global market for activated alumina will be valued at approximately $2.5 billion in 2024, with an anticipated annual growth rate of 5.3% through 2032. Its varied applications include water purification to remove contaminants like fluoride and arsenic, air drying, and gas purification. Oil refining and hydrogen production industries also utilize activated alumina as a catalyst support.

Contents

- 1 What is Activated Alumina?

- 2 Alumina Meaning

- 3 What is Activated Alumina in Chemistry?

- 4 What is Activated Alumina Made Of?

- 5 Activated Alumina Chemical Formula

- 6 How Activated Alumina is Formed?

- 7 Chemical Composition and Activation

- 8 Role of the Chemical Formula in Applications

- 9 Activated Alumina Formula

- 10 Breakdown of the Formula

- 11 Key Properties Related to the Formula

- 12 Activated Alumina Properties

- 13 Activated Alumina Filter: A Key Solution for Water Purification

- 14 Activated Alumina vs Silica Gel: A Comparison

- 15 Activated Alumina Beads: Efficient Adsorbents for Purification

- 16 Activated Alumina for Arsenic Removal: A Powerful and Cost-Effective Solution

- 17 Activated Alumina Cartridge: Effective Filtration for Water and Gas Purification

- 18 Active Alumina Powder: Versatile Adsorbent for Filtration and Industry

- 19 Activated Alumina Specifications: Key Features and Performance Parameters

- 20 Conclusion

What is Activated Alumina?

Activated alumina is a unique material created from aluminum oxide (Al₂O₃), designed to have a large surface area for adsorbing various substances. To produce it, aluminum hydroxide (Al(OH)₃) is subjected to heat at temperatures between 1000°C and 1100°C, transforming it into a highly porous form. This porosity allows the material to adsorb moisture, gases, and even specific ions, making it extremely useful in several industrial applications.

What sets activated alumina apart from regular alumina is its high adsorption capacity. After activation, the surface area of activated alumina is significantly higher, allowing it to capture molecules like water, organic compounds, and even some heavy metals. As a result, it is commonly used in industries requiring moisture control, such as in air purification systems where it removes water from gases. It's also a key material in water filtration processes, where it efficiently filters out contaminants like fluoride and arsenic.

In addition to its filtering abilities, activated alumina is used in catalytic processes, especially in petroleum refining, which helps purify and process gases and liquids. The material is also regenerated by heating it to high temperatures, releasing the adsorbed substances, and allowing it to be reused. This makes activated alumina a cost-effective and sustainable solution for industries with high demand for filtration and purification.

As the need for cleaner air, water, and more sustainable industrial processes grows, activated alumina remains essential in achieving these goals. Its ability to effectively adsorb impurities and its renewability make it a valuable resource across many sectors, from environmental protection to energy production.

Alumina Meaning

Alumina, chemically known as aluminum oxide (Al₂O₃), is a white, crystalline substance that plays a pivotal role in various industrial sectors. It is primarily derived from bauxite ore through the Bayer process, which separates alumina from impurities. With a high melting point and great thermal and electrical insulating properties, alumina is a key material in industries ranging from metallurgy to ceramics. In particular, it serves as the key precursor in aluminum production, where it is reduced to produce aluminum metal, a material essential for manufacturing a wide range of products, from lightweight vehicles to high-tech electronics.

As of December 2024, global alumina production exceeds 130 million metric tons annually, with leading producers like China, Australia, and Brazil driving the supply chain. Alumina is central to aluminum production and has growing applications in water purification, gas adsorption, and as a catalyst in chemical processes. Activated alumina, for example, is used to filter air and water, making it an integral part of environmental sustainability efforts. Its role in innovation and efficiency, especially in industries focused on clean energy and high-performance materials, highlights its importance in modern manufacturing and ecological solutions.

What is Activated Alumina in Chemistry?

Activated alumina is a highly porous and reactive form of aluminum oxide (Al₂O₃) that has been specially treated to enhance its surface area and adsorptive properties. In chemistry, it is primarily used as an adsorbent material in various industrial applications due to its ability to absorb specific molecules selectively. Activated alumina's high surface area and affinity for certain gases and liquids make it essential in water purification, air filtration, and catalyst support. It can effectively remove impurities from water and gases, including fluoride, arsenic, and sulfur compounds, making it a crucial material in environmental and chemical industries.

As of 2024, activated alumina has expanded significantly due to its effectiveness in various applications. In the water treatment industry, it is commonly used to remove toxic substances like fluoride and arsenic, ensuring safe drinking water. Additionally, activated alumina is employed in the oil and gas industry for desulfurization and drying gases and liquids, which helps remove moisture. Its versatility in chemical processes, particularly in catalysts and adsorption, continues to highlight its critical role in industrial and environmental chemistry.

What is Activated Alumina Made Of?

Activated alumina is a specialized industrial substance extensively used in numerous processes, such as purifying gases and water and catalyzing chemical reactions. This material predominantly comprises aluminum oxide (Al2O3), which undergoes particular industrial treatments to effectively capture and eliminate harmful contaminants from the surroundings. The activation process for alumina typically involves heating it to very high temperatures (around 500 to 600°C) for several hours to create a porous and absorbent structure, enabling alumina to absorb a significant volume of various gases or liquids.

The raw materials for producing activated alumina are mainly extracted from bauxite mines. Bauxite, a rock rich in aluminum oxide, was first identified in 1821 by the French scientist Pierre Berthier. Through a hydration process, alumina is separated from bauxite and then activated at high temperatures. In simple terms, activated alumina has a microscopic structure with a significantly increased surface area. This increase in surface area is due to the numerous pores and voids within the alumina's structure, making it ideal for various applications such as water and gas purification.

In recent decades, the demand for activated alumina has significantly increased. According to a 2023 global market report, the demand for activated alumina in water and gas purification industries has grown by more than 10% annually. It is used in water treatment systems to remove organic materials and heavy metals. Furthermore, activated alumina effectively captures contaminants like hydrogen sulfide and carbon dioxide within the oil and gas sectors.

In the energy industry, especially in energy storage batteries like Flow batteries, activated alumina is increasingly used to absorb ions and gases in energy storage processes. Projections suggest that by 2030, the use of activated alumina in energy storage industries, particularly in ion batteries and fuel cell systems, will significantly increase.

The increasing need for activated alumina and its diverse uses across multiple sectors have prompted manufacturers to consistently focus on research and development. Producers of activated alumina, including those specializing in activated alumina balls and desiccants, are dedicated to enhancing their production methods and minimizing expenses to effectively meet global market demands.

Activated Alumina Chemical Formula

The chemical formula of activated alumina is primarily Al₂O₃, which stands for aluminum oxide. This is the essential component of activated alumina, and its structure is made up of aluminum and oxygen atoms bonded together in a stable, crystalline form. However, activated alumina is not a pure, single-phase material like aluminum oxide; it is a highly porous, activated form of alumina, which undergoes additional processes to increase its surface area and enhance its adsorption capabilities.

How Activated Alumina is Formed?

Activated alumina is derived from bauxite, a naturally occurring mineral containing aluminum oxide (Al₂O₃), iron oxide (Fe₂O₃), and other impurities. To obtain pure aluminum oxide (Al₂O₃), the bauxite is processed using the Bayer process, which is refined to remove impurities. This refined aluminum oxide undergoes thermal activation at high temperatures (500-600°C) to form activated alumina. The activation process causes a structural transformation that creates a highly porous material with a significant surface area, making it ideal for adsorption applications.

Chemical Composition and Activation

Activated alumina retains the basic chemical structure of aluminum oxide (Al₂O₃). Still, its key feature is its increased surface area and porosity, which are created during the activation process. This transformation occurs when the material is heated in controlled conditions, allowing it to develop numerous micropores and macropores that significantly enhance its capacity to adsorb gases, liquids, and other molecules.

Although the chemical formula remains Al₂O₃, the surface of the material interacts with various substances, leading to reactions that are often part of the adsorption process. In addition to aluminum oxide, trace elements such as sodium (Na) or silicon (Si) may also be present depending on the source material and the manufacturing process.

Role of the Chemical Formula in Applications

The Al₂O₃ structure of activated alumina makes it chemically stable and resistant to thermal degradation, which is one reason it is effective in high-temperature applications. The porosity and surface area of the material, which result from the activation process, are more important than the precise chemical composition in most industrial applications. This makes activated alumina useful for a range of purposes, such as:

- Gas purification: It can adsorb gases like sulfur compounds and carbon dioxide.

- Water treatment: Activated alumina removes fluoride, arsenic, and other contaminants from drinking water.

- Desiccants: Its high surface area makes it ideal for moisture removal in various industrial processes.

Activated Alumina Formula

The formula for activated alumina is Al₂O₃, which represents aluminum oxide. Activated alumina is a highly porous and activated form of aluminum oxide created through a specific process that enhances its surface area and adsorption properties. While the chemical composition remains Al₂O₃, the material undergoes an activation process that makes it highly porous, allowing it to absorb gases, liquids, and other substances effectively.

Breakdown of the Formula

- Al stands for aluminum.

- O₃ indicates the presence of three oxygen atoms, bonding with two aluminum atoms to form aluminum oxide.

Even though the fundamental formula is Al₂O₃, during the activation process, the material develops a vast network of tiny pores and cavities, which significantly increases its surface area (often reaching up to 350 m²/g or more). This porous structure gives activated alumina its unique properties as an adsorbent material.

While Al₂O₃ is the basic chemical formula, it's important to note that activated alumina is not pure aluminum oxide. It is a form of alumina that has been processed (or activated) under high temperatures (typically between 500-600°C) to create this highly porous structure. Some trace elements (like sodium, silicon, or iron) might also be present depending on the raw material and the specific activation method.

Key Properties Related to the Formula

- High Surface Area: The activation process increases the material's surface area, making it ideal for adsorption applications.

- Porosity: Activated alumina's structure comprises numerous micropores and macropores, which enhance its ability to trap gases and liquids.

- Chemical Stability: The alumina structure remains chemically stable, allowing activated alumina to withstand high temperatures and harsh environments.

Activated Alumina Properties

Activated alumina is distinguished by several essential characteristics that contribute to its efficiency in various industrial and environmental uses. These attributes are primarily a result of its distinctive porous framework formed during the activation process. Below is a summary of the key features of activated alumina:

- Extensive Surface Area

One of the standout features of activated alumina is its extensive surface area, which can exceed 350 m²/g depending on how it is activated. The activation process generates countless tiny pores and voids, significantly enlarging the surface available for adsorption. This characteristic renders it especially ideal for uses that require absorbing gases, liquids, and various other materials.

- Porous Structure

Activated alumina's highly porous nature significantly boosts its adsorption capacity. It contains micropores (with diameters under 2 nanometers) and macropores (larger openings), crucial for capturing diverse substances. Micropores attract smaller molecules like gases, while macropores can adsorb larger entities such as liquids and heavier pollutants.

- Chemical Resilience

This material exhibits remarkable chemical stability even in extreme conditions. Activated alumina can endure elevated temperatures—typically ranging from 500 to 600 °C—without deterioration, making it suitable for high-temperature applications like gas purification and energy storage systems. Additionally, it shows resistance to most chemicals, rendering it ideal for various industrial contexts where stability is paramount.

- Significant Adsorption Capacity

Thanks to its porous design and substantial surface area, activated alumina boasts an impressive adsorption capacity. It excels at capturing gases, water vapor, and specific ions. It is commonly employed in water treatment processes to eliminate fluoride, arsenic, and other impurities and in air purification systems to absorb sulfur compounds and carbon dioxide.

In summary, activated alumina is an effective desiccant with versatile applications across multiple industries due to its unique properties.

Activated Alumina Filter: A Key Solution for Water Purification

Activated alumina filters are highly effective in water purification systems, offering a specialized solution for removing contaminants such as fluoride, arsenic, and sulfur compounds. The activated alumina water filter utilizes this porous material to adsorb harmful substances, ensuring cleaner and safer drinking water.

With its high surface area and adsorption capacity, activated alumina filtration is a preferred method for treating both drinking and industrial water supplies, providing long-lasting performance and efficient contaminant removal. Whether used in home filtration units or large-scale water treatment facilities, activated alumina filters play a crucial role in maintaining water quality.

Activated Alumina vs Silica Gel: A Comparison

Activated alumina and silica gel are both effective desiccants, but they have distinct properties and applications. Activated alumina is a highly porous, granular material made from aluminum oxide, commonly used for removing water, fluoride, and other contaminants from gases and liquids. It has a high surface area and is especially effective in applications requiring selective adsorption, such as in water purification or gas drying.

Silica gel, on the other hand, is made from silicon dioxide and is primarily used to control humidity and moisture in enclosed environments. It is less selective than activated alumina and mainly adsorbs water vapor. Silica gel is commonly found in desiccant packets used to protect products from moisture during storage or transportation.

While both materials excel at moisture removal, activated alumina is more specialized for chemical filtration. At the same time, silica gel is best suited for moisture control in non-chemical environments.

Activated Alumina Beads: Efficient Adsorbents for Purification

Activated alumina beads are small, porous, and highly absorbent spheres made from aluminum oxide (Al₂O₃). These beads are commonly used in various applications, such as water purification, air drying, and gas dehydration.

Their high surface area and porosity make them excellent at adsorbing moisture, fluoride, arsenic, and other contaminants from liquids and gases. In water filtration, activated alumina beads are particularly effective at removing fluoride, heavy metals, and sulfur compounds, ensuring cleaner, safer water.

Additionally, they are used in desiccators, catalysts, and adsorbents in various industrial processes. Their durability and reusability make them a preferred choice for many applications requiring moisture control and contaminant removal.

Activated Alumina for Arsenic Removal: A Powerful and Cost-Effective Solution

Activated alumina is one of the most effective materials for removing arsenic from drinking water. Its high surface area and porous structure allow it to adsorb arsenic ions efficiently, targeting both the more toxic trivalent (As³⁺) and pentavalent (As⁵⁺) forms. This makes activated alumina a highly versatile solution for treating water contaminated with arsenic, which is a significant concern in many regions worldwide, particularly in areas with contaminated groundwater.

The process involves passing water through a bed of activated alumina, where the arsenic is adsorbed onto the surface of the beads, significantly reducing its concentration to safe levels. This filtration method not only provides an affordable and effective way to remove arsenic but also ensures that the treated water meets international safety standards.

Activated alumina’s ability to selectively adsorb arsenic makes it suitable for both small-scale home filtration systems and large-scale municipal water treatment plants. Additionally, it has a longer lifespan compared to other filtration media, reducing maintenance costs and ensuring long-term protection from arsenic exposure. Because of its proven effectiveness, activated alumina is widely used in regions facing arsenic contamination, offering a sustainable solution for improving public health.

Activated Alumina Cartridge: Effective Filtration for Water and Gas Purification

An activated alumina cartridge is a filtration device that contains activated alumina beads or granules, which are used for removing contaminants such as fluoride, arsenic, and other heavy metals from water or gas streams. The cartridge typically fits into water filtration systems, air dryers, or industrial gas purification units.

Activated alumina's extensive porosity enables it to capture various contaminants effectively, making it a preferred option for use in both home and industrial settings. In water filtration, activated alumina cartridges are particularly effective at removing harmful substances like fluoride and arsenic, providing cleaner, safer drinking water. They are also used in air and gas purification to remove moisture, sulfur compounds, and other impurities.

Activated alumina cartridges offer a cost-effective and long-lasting filtration solution. They can be easily replaced or regenerated to maintain optimal performance, making them an efficient choice for long-term contaminant removal. Whether used in household water purifiers or large-scale industrial processes, activated alumina cartridges play a key role in ensuring clean, high-quality water and air.

Active Alumina Powder: Versatile Adsorbent for Filtration and Industry

Active alumina powder is a highly porous and finely ground form of aluminum oxide (Al₂O₃), known for its excellent adsorption properties. With a surface area typically ranging from 200 to 350 m²/g, it is highly effective in adsorbing a wide variety of contaminants, such as fluoride, arsenic, sulfur compounds, and moisture.

Its fine particle size enhances its efficiency in filtration and purification processes, enabling it to remove contaminants from both liquids and gases. Active alumina powder is particularly valuable in water treatment applications, where it helps to significantly reduce the concentration of harmful substances like fluoride and heavy metals, ensuring cleaner, safer water for consumption.

In addition to its use in water purification, active alumina powder is utilized in various industrial sectors because of its chemical stability and sustainability. It is commonly used in gas purification systems for drying natural gas, air, and other industrial gases, as well as in moisture control for sensitive products.

Its ability to function as a catalyst support in chemical processes, such as petroleum refining and petrochemical production, further enhances its versatility. Active alumina powder can be regenerated by heating or using suitable chemical treatments. It is a cost-effective material for long-term use in various filtration, drying, and catalysis processes.

Activated Alumina Specifications: Key Features and Performance Parameters

Activated alumina is a versatile material used in various filtration and purification applications. The specific characteristics of activated alumina can vary depending on its intended use, but the following are typical specifications:

- Chemical Composition:

- Primary Component: Aluminum oxide (Al₂O₃)

- Impurities: Depending on the manufacturing process, trace amounts of silica (SiO₂), iron oxide (Fe₂O₃), and other minerals may be present.

- Physical Properties:

- Surface Area: Typically 200–350 m²/g

- Pore Volume: Approximately 0.3–0.4 cm³/g

- Particle Size: Often in the range of 0.5–3 mm (for beads) or powder form, depending on the application

- Bulk Density: Around 0.5–0.7 g/cm³

- Porosity: High, typically greater than 40%

- Adsorption Capacity:

- Fluoride Removal: Depending on concentration and contact time, it can remove up to 90–95% of fluoride from water.

- Arsenic Removal: Capable of removing up to 99% of arsenic in both its As(III) and As(V) forms.

- Moisture Adsorption: Can adsorb moisture and gases such as sulfur compounds and carbon dioxide in air and gas purification applications.

- Regeneration:

- Heated treatment can restore activated alumina to its functional state at 300–400°C or by using mild acid or alkali solutions, depending on the type of contamination and application. This makes it reusable for long-term use in filtration systems.

- Operational Temperature Range:

- It can withstand temperatures from -50°C to 500°C, with variations depending on specific applications and conditions.

- pH Range for Water Filtration:

- It is typically effective for water treatment within a pH range of 4 to 8. However, depending on its formulation, it can also handle more extreme pH levels in some cases.

- Packaging:

- Available in granular, bead, or powdered forms, depending on the filtration or purification needs.

These specifications can vary by the exact use case or other factors, but in general, activated alumina is known for its high adsorption efficiency, durability, and cost-effectiveness in removing a range of contaminants from water and gas systems.

Conclusion

Activated alumina is an exceptionally efficient and adaptable substance that finds extensive use in numerous filtration and purification processes.

Whether in the form of activated alumina balls for water treatment or as an activated alumina desiccant for moisture control, Thanks to its extensive surface area and porous design, it provides exceptional adsorption capabilities.

Its ability to remove harmful contaminants like fluoride, arsenic, and heavy metals from water, as well as moisture and gases from air and industrial processes, makes it indispensable across multiple industries.

The reusability and regenerability of activated alumina further enhance its cost-effectiveness, ensuring long-term performance and sustainability in diverse applications.